CVD (Chemical Vapor Deposition) from aerosols is one of the catalytic CVD methods. This method is based on the catalytic decomposition of a liquid or gaseous hydrocarbon, such as toluene or acetylene, in the presence of a metallocene such as ferrocene. The specificity of the process developed at LEDNA lies in the fact that it is accomplished in a single step: the reactor is supplied simultaneously with a catalytic source and a carbon source. LEDNA has different equipment depending on the direction of injection of the precursors and the size of the samples synthesized:

- Equipment in horizontal configuration making it possible to obtain samples with a surface area of the order of one cm² to a few tens, or even hundreds of cm²;

- Equipment in vertical configuration making it possible to obtain samples with a surface area of the order of several hundred cm²

All this equipment is composed of 3 parts: an aerosol generator making it possible to produce a set of droplets most often accompanied by an evaporator, an oven in which a reactor is placed and a set of cooling and evacuation systems. gas released during synthesis.

Two types of aerosol generators are used: an ultrasonic aerosol generator or an automotive injector-type injection system. The ultrasonic aerosol generator is made up of a piezoelectric ceramic which vibrates and creates, by micro-cavitation, an aerosol on the surface of the liquid, which is then transported by the gas flow. The injector system consists of a needle valve whose opening is controlled in duration and frequency and it operates in pulsed mode.

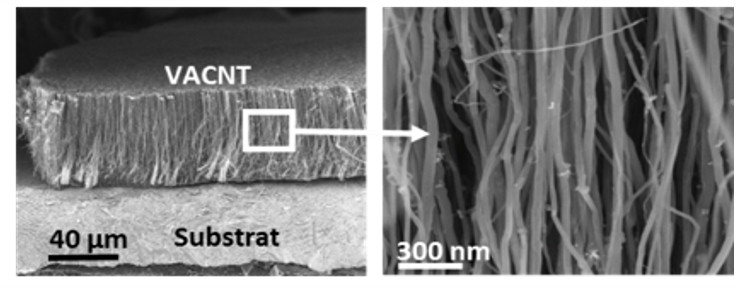

The decomposition of catalytic and carbon precursors occurs in two stages. Initially, the metallocene will decompose thermally giving rise to the formation of catalytic particles in the gas phase [Castro et al., Carbon 2010 – 2013] which will, secondly, generate the catalytic decomposition of the carbon precursor. This results in the formation of a deposit on the reactor walls or on various substrates (quartz, silicon, stainless steel, aluminum, carbon and carbon fiber fabrics, etc.). This deposit is made up of carbon nanotubes aligned like a brush carpet.

Small equipment in horizontal configuration is also used for the growth of graphene on metals.

LEDNA also develops equipment specifically dedicated to the in-situ study of the formation of nanotubes or graphene directly during their synthesis.