Develop methods to produce completely new materials with original properties.

NIMBE’s (nano)materials axis federates interdisciplinary activities around the study of materials at different scales, in their volume or on the nanometric scale. These different (nano)materials are synthesized using original protocols and devices, many of them equipped with in situ diagnostics. From the elementary brick to their 1D, 2D or 3D organization, the aim is to master the design and synthesis, fine characterization and shaping, as well as the measurement of the properties of these (nano)materials in response to scientific questions and/or applications responding to societal and environmental issues. The ambitions of this (nano)materials axis include mastering materials for the energy transition, taking into account recycling and, more generally, the life cycle, developing a Safe and Sustainable by Design (SSbD) approach right from the design stage, developing new synthesis processes that are more respectful of the environment, understanding the underlying mechanisms of formation and aging to improve design, etc. This axis is in close interaction with the three other NIMBE thematic axes.

The (nano)materials axis brings together around 60 permanent staff and is divided into 4 sub-axes:

Synthesis processes and in situ diagnostics

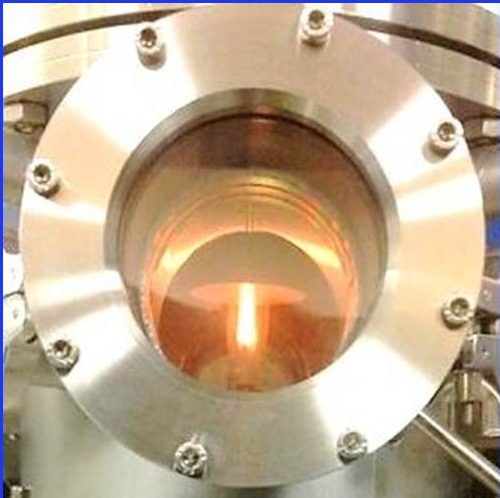

NIMBE has developed considerable expertise in innovative processes for preparing new nanomaterials, characterizing them and analyzing their properties. Particular emphasis is placed on the instrumental development of new techniques for characterizing and shaping samples at different scales. This knowledge, and the complementary nature of the many characterization tools available, enables multi-scale control of the entire value chain (synthesis – characterization – devices – uses).

NIMBE has unique instruments for exploring the compositions and dimensions of materials, as well as their physical and chemical properties. Some of these instruments are grouped together in platforms open to the community. Ultimately, mastering nanomaterials requires an understanding of the mechanisms underlying their formation, organization and integration into a device. To meet this challenge, the NIMBE has for several years been developing specific know-how in in situ and/or operando characterization tools on a laboratory scale or in conjunction with large-scale instruments. The coupling of theory and experiment, and the development of processing and prediction methodologies, have led to major advances in the synthesis of new (nano)materials and innovative devices.

Heritage materials

The specificity of heritage materials lies in the complexity of these systems, whose physicochemical characteristics (microstructure, composition) are heterogeneous right down to the nanometric scale. The studies carried out at NIMBE focus on heritage materials in two main areas:

– understanding historical production (metals, glass and, for more recent materials, plastics) through interdisciplinary collaboration (historians, archaeologists)

– studying the effect of time on their evolution.

These issues are of interest to industrialists, who can benefit from feedback on the state of degradation of these materials under natural conditions (e.g. evolution of the chemistry and mechanical properties of plastics). They can also be used as analogues to predict the long-term behavior of materials used in radioactive waste disposal (archeological ferrous analogues for steel corrosion, vitreous analogues for waste packages). Different methodologies combining multi-scale techniques to determine the properties of these ancient materials are needed to understand the fine mechanisms of degradation. Finally, one area is dedicated to the development of innovative treatments for the preservation of these heritage objects, within the framework of themes initiated in conservation-restoration.

Hybrid and composite systems

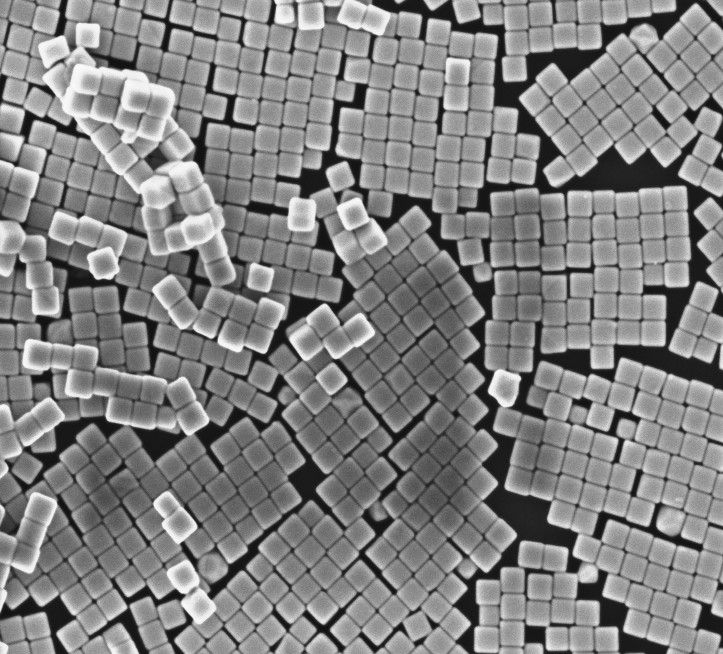

At NIMBE, numerous families of materials and nanomaterials are elaborated by solid, liquid or gaseous means, then finely characterized. These materials of different dimensions can then be combined to tailor their physico-chemical properties. The syntheses developed at NIMBE are numerous and cover different states of matter, from gas-phase syntheses (laser or flame pyrolysis, CVD) to solution syntheses (colloid, sol-gel, electrochemistry, grafting). The shaping of these (nano)materials requires the adjustment or development of innovative processes such as surface coatings (spin coating, dip-coating, PVD, coating, etc.), sintering, casting, etc., or the combination of existing or specifically developed processes. The resulting hybrid or composite systems are then studied for their properties in different fields of application, such as: heterojunctions for (photo)catalysis, hybrid materials for energy storage or the environment, sensors or nano-vectors for biology, heterostructures and components for electronics and optics, structural materials,…. These hybrid and composite materials are often developed in close collaboration with industry.

Materials of the future for electronics and optics

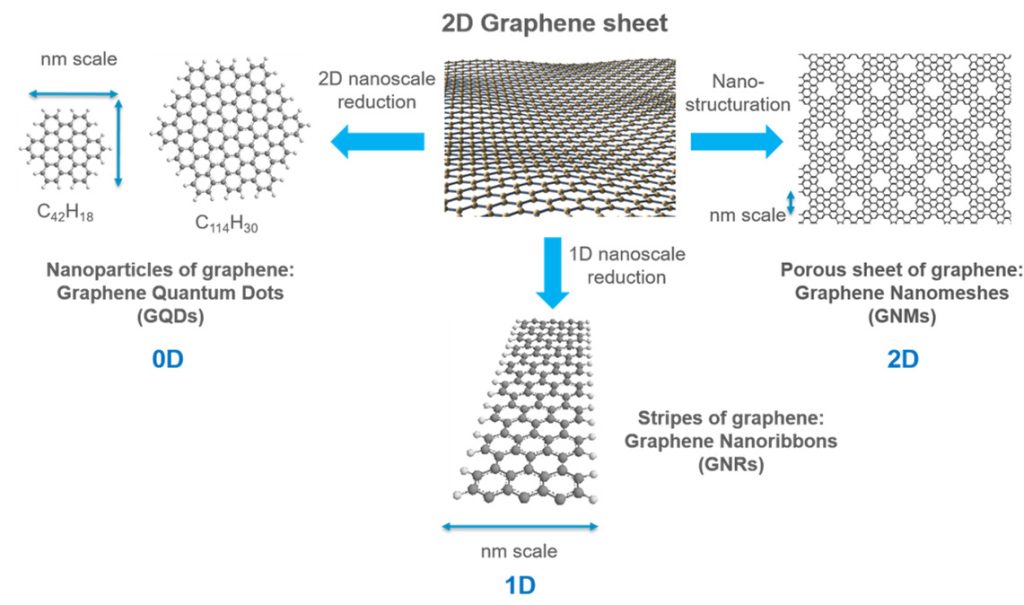

Nanomaterials have great potential for use as building blocks in the design of electronic, optical and optoelectronic devices. Indeed, their size and dimensionality (0D, 1D, 2D) have a major impact on their optical and electronic properties, which can be exploited in innovative devices. NIMBE researchers are studying several classes of nanomaterials and their integration into devices (transistors, phototransistors, OLEDs, etc.). Examples include

– the study of single-photon emission from chemically synthesized graphene nanoparticles (link 1)

– the integration of chirally sorted carbon nanotubes as infrared light sources and detectors at telecom wavelengths (link 2)

– the operando study of charge density in two-dimensional MoS2-based transistors (link 3).