The aerosol-based CVD (Chemical Vapor Deposition) method developed at LEDNA enables the synthesis of aligned carbon nanotubes (VACNTs) in the manner of a carpet-brush, virtually free of by-products and whose length can be controlled over a wide range. LEDNA is able to produce VACNTs on substrates of various kinds and with predetermined characteristics (diameter, length, density). The method developed operates in a single step, with carbonaceous and catalytic precursors injected simultaneously into the reactor. It’s a low-cost process that has been developed right through to industrial production, and has prompted the creation of a start-up company, NawaTechnologies. The aim is to master this process in order to synthesize aligned nanotubes with controlled physico-chemical characteristics for various applications. To achieve this, it is crucial to understand how these nanotubes grow.

The synthesis temperature most often used is around 800°C. Growth can take place directly on the reactor walls or on substrates (quartz, silicon, metals, carbon materials, etc.). For growth on metals or carbonaceous substrates, the deposition of an SiOx barrier underlayer is necessary to avoid carbon accumulation in the substrate (Delmas et al., Nanotechnology 2012). This deposition precedes the feeding of the reactor with the precursors required (ferrocene dissolved in toluene) for CNT growth. Recently, the switch to a gaseous carbon source, namely acetylene, has enabled the synthesis temperature to be lowered to less than 650°C. This change now makes it possible to obtain carbon nanotubes that are thinner (diameter of around 10 nm vs. 20 or 40 nm at higher temperatures, see figure) and denser(1011 vs. 109 CNT/cm² at higher temperatures), and to grow them on low-melting-temperature substrates such as aluminum.

Study of the growth mechanisms of vertically aligned carbon nanotubes by CVD (Materials & nanomaterials axis)

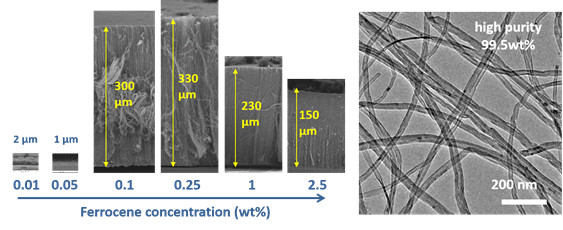

The particular alignment of carbon nanotubes synthesized by chemical vapor deposition (CVD), as well as the control of their length, alignment, diameter or structural organization are undeniable assets for the exploitation of the specific characteristics of VACNTs. The control of these characteristics requires a better understanding of the phenomena at work during their formation according to the growth conditions used. During the period evaluated, significant progress was made in understanding growth at medium temperature [1] by significantly reducing the percentage of Iron during synthesis, which leads to cleaner and better structured VACNTs (figure)[2]. Major progress was mainly made at low temperature on Al collectors, in particular by overcoming the limitation of achievable carpet thicknesses linked to the deactivation of catalytic particles. While maintaining a growth rate among the highest in the state of the art for this type of synthesis process, the work carried out on the control of the Fe/C ratio of the precursors, high density VACNT thicknesses and several hundred µm on Al are now accessible [3]. This development of the efficient growth of CNTs at low temperature on metals, however, requires a finer understanding of the growth mechanisms in these temperature ranges where the kinetics of the physicochemical phenomena at work is slow. This encourages us to direct our fundamental studies in the future towards approaches based on our know-how in in-situ analysis, the specific experimental implementation of which at low temperature and ductile substrate (Al) was initiated during the period.

Long and high density vertically aligned carbon nanotubes (VACNT) on lightweight metal collectors for electrode materials (energy axis)

In terms of valorization of the specific characteristics of aligned CNTs, our attention is focused on the design of innovative devices, particularly for applications as energy storage devices [4]. These efforts have resulted over the period in the work carried out in academic and industrial collaboration within the joint NAWALab laboratory (aiming to transpose the controlled growth of these nanostructures onto Al supports of industrial interest [5].

Beyond these applications of VACNTs linked to the energy sector, an important line of study is being conducted in the field of structural materials in the form of an industrial contract (CEA/CNES) evaluating the interest of CNTs in the materials of tanks containing cryogenic fluids for space applications. After demonstrating the contribution of the presence of CNTs in the composite material on its behavior in these temperature ranges, the first achievements of VACNT/polymer composites by two different association routes with carbon fibers in direct growth or following a transfer process have been validated [6]. This work is currently finding new momentum with a thesis project focusing on the definition of a preferred route for associating all of these building blocks for the development of laminated carbon fiber composite materials.

[1] C. Castro et al., ‘Analysis of the Continuous Feeding of Catalyst Particles during the Growth of Vertically Aligned Carbon Nanotubes by Aerosol-Assisted CCVD’, Nanomaterials, 2022, 12, 449. https://doi.org/10.3390/nano12030449

[2] E. Charon et al., “One-step synthesis of highly pure and well-crystallized vertically aligned carbon nanotubes”, Carbon, 173, 2021, 758-768. https://doi.org/10.1016/j.carbon.2020.10.056

[3] A. Combrisson, E. Charon, M. Pinault, C. Reynaud et M. Mayne-L’Hermite, ‘Critical Role of the Acetylene Content and Fe/C Ratio on the Thickness and Density of Vertically Aligned Carbon Nanotubes Grown at Low Temperature by a One-Step Catalytic Chemical Vapor Deposition Process’, Nanomaterials 2022, 12, 2338 https://doi.org/10.3390/nano12142338

[4] T. Vignal et al., ‘Electropolymerized poly(3-methylthiophene) onto high density vertically aligned carbon nanotubes directly grown on aluminum substrate: Application to electrochemical capacitors’, Electrochimica Acta 350, (2020), 136377, https://doi.org/10.1016/j.electacta.2020.136377

[5] C. Querne et al., ‘A comparative study of high density Vertically Aligned Carbon Nanotubes grown onto different grades of aluminum – Application to supercapacitors’, Journal of Power Sources, 2023, 553, 232258, https://doi.org/10.1016/j.jpowsour.2022.232258

[6] J. Bouillonnec et al., ‘Study of carbon nanotube/cyanate ester composite materials dedicated to cryogenic storage vessels’, proceeding of 9TH EUROPEAN CONFERENCE FOR AERONAUTICS AND SPACE SCIENCES (EUCASS), 2022

NIMBE Research Axis