Securely Advancing Future EVs with Li-IOn batteries through Optimized Pathways

- Objective

Envisioned battery demand of 735 GWh for electric mobility by 2025, escalating to a projected 125 million Electric Vehicles (EVs) by 2033, fuels our impetus for innovation. However, these prospects are marred by real safety concerns, evidenced by 2 harrowing ship fires involving luxury EVs, despite adherence to the most stringent safety protocols. SAFELOOP is a collaborative effort involving 15 entities from 11 countries, representing a blend of research, manufacturing, and business across Europe. Transatlantic partners are joining forces to bolster competitive material-level technologies and supply chain logistics. Key goals include securing strategic raw material feedstock, reducing reliance on Asian supply chains, intensifying environmental sustainability, optimizing energy-efficient processing, and demonstrating technological leadership. SAFELOOP’s focal point is Gen3 EU EV Li-Ion Battery (LIB) safety, encompassing the entire life cycle of LIBs within EVs. Safety is considered in a broader sense, not just at a cell level, while the latter remains a key pillar of the research at hand. To name a few, material handling, component processing, battery manufacturing, testing, transport, maintenance, and recycling of active materials are considered. A Eurocentric supply chain for EV-grade battery materials will be established, minimizing the environmental and cost impact of long-distance transportation. SAFELOOP ensures that batteries and their components adhere to EU safety and environmental regulations. Beyond enhancing EU battery safety, the project seeks to develop the world’s first EV-rated LIB using up to 25% recycled and fully rejuvenated battery-active materials. This initiative paves the way for an ambitious industry-wide recycling target of 90% within the next decade, akin to today’s lead-acid battery industry’s 95% recycling rate. These ecologically responsible solutions address key aspects of automotive battery safety within the EU and beyond

- Our task

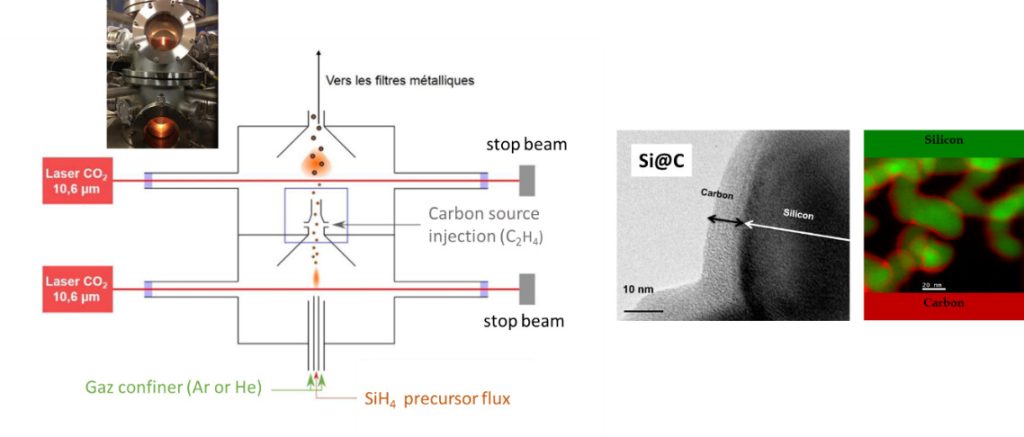

Our team will synthetize non-agglomerated silicon and carbon coating silicon nanoparticles by Laser pyrolysis method. Novel silicon-based composites made from natural and recycled graphite materials will study as anode materials for lithium-Ion battery.

Project coordination: Oulun Yliopisto (Oulou, Finland)

Partners: 15 organizations (13 partners and 2 associated partners from US and Australia)

ANR project : online outcoming asap