Anne-Sophie Robbes, Jacques Jestin, Florian Meneau, Florent Dalmas, François Boué, and Fabrice Cousin, Macromolecules 2022, 55, 15, 6876–6889.

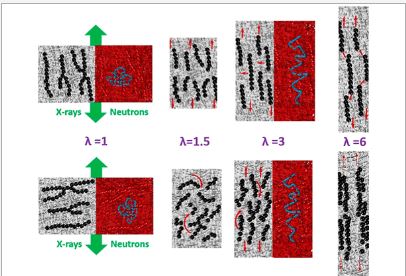

We present a combined detailed monitoring of the respective evolutions of the structure of fillers by SAXS and conformation of polymeric chains by SANS under uniaxial stretching at various elongation ratios in a nanocomposite made of spherical magnetic nanoparticles of γFe2O3 dispersed in a matrix of polystyrene (PS) chains. We can make the structure of fillers in the nanocomposite before stretching very anisotropic, as we demonstrated in reference (Macromolecules,2011,44(22), 8858–8865), thanks to the appliance of a magnetic field during the nanocomposite processing that induces the formation of nanoparticle chains aligned along the direction of the field, either parallel or perpendicular to the subsequent stretching. This gives rise to very anisotropic mechanical properties, and the structure of fillers evolves very differently. In the parallel case, there is a rupture of the chains of nanoparticles into smaller subunits that progressively align completely in the stretching direction. In the perpendicular case, the chains first rotate, to eventually reorient along the stretching direction, gradually breaking themselves. Finally, at a very large elongation rate (λ = 6), the organization of nanoparticles in both cases converge toward a common structure made of small chains of nanoparticles completely oriented along the stretching. The chain conformation is directly obtained by SANS as we probed samples containing 25% PSH/75% PSD chains, taking benefit from the fact that the neutron scattering length density of PSD is similar to the one of γFe2O3. Strikingly, the deformation of the polymer chains is the same as in the reference PS matrix without fillers, whatever stretching is parallel and perpendicular to the chains of nanoparticles at λ = 3. The chains scattering exhibit the typical features of those of the former studies of relaxation during or after stretching on pure melts, accounting for the relatively slow deformation rate, the distance from Tg (15 °C) their average masses, and their large polydispersity.