Thin layers of tantalum pentoxide (Ta₂O₅) are key materials for optical and photonic applications, thanks to their high refractive index and low extinction coefficient. These properties make them ideal candidates for interference filters, anti-reflective coatings, optical waveguides, and microelectronic devices. However, their performance depends heavily on deposition conditions and heat treatments. Researchers have studied how to precisely adjust these parameters to achieve the best compromise between transparency, high refractive index, and structural stability, paving the way for new high-performance optical materials.

Thin layers of Ta₂O₅ are attracting considerable interest in optical and electronic devices due to their high refractive index (n ~ 2.1–2.3) and low extinction coefficient (k < 10⁻⁴), two properties that are essential for the manufacture of high-precision optical devices. However, their optical and structural performance depends heavily on deposition conditions and post-deposition heat treatments. Prior to this study, cathodic sputter-deposited layers exhibited significant variations in their properties, with an amorphous phase favored for its transparency but a lower refractive index than the crystalline phase. However, the latter is associated with structural defects and increased optical losses, limiting their use in certain applications.

In this study, researchers deposited thin layers of Ta₂O₅ on silicon using radiofrequency (RF) sputtering, varying the power density (2.19 to 6.57 W/cm²), oxygen flow rate (0 to 16 sccm), and rapid thermal annealing (RTA) temperature (450 °C to 850 °C). The structural properties were analyzed by X-ray diffraction (XRD), infrared spectroscopy (FTIR), and transmission electron microscopy (TEM), while the optical properties were characterized by spectroscopic ellipsometry and spectrophotometry.

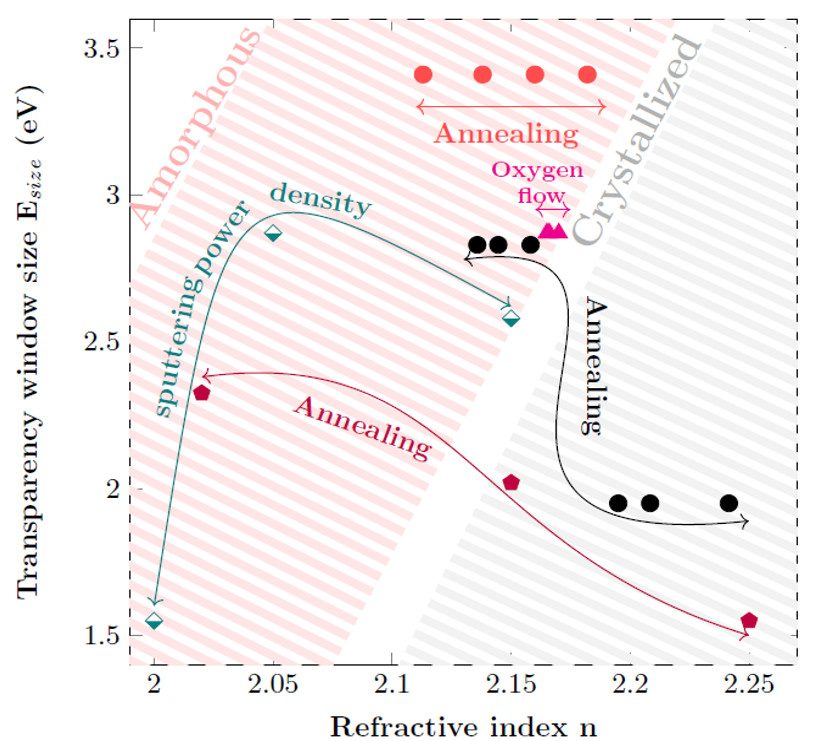

This study enabled several major findings to be highlighted: a Ta/O ratio close to stoichiometry (0.38) was obtained for a power density of 3.29 W/cm² and an oxygen flow rate of 8 sccm, providing an optimal composition for stable optical properties. Crystallization, initiated at 650 °C, leads to a dominant orthorhombic phase (β-Ta₂O₅) at higher temperatures, as confirmed by X-ray diffraction (XRD) and transmission electron microscopy (TEM). The refractive index (n) thus reaches a maximum of 2.24 at 750 °C, before decreasing to 2.18 at 850 °C due to densification and then structural degradation. In addition, the extinction coefficient (k) undergoes a redshift, changing from 4 eV to 3 eV after crystallization, reflecting an increase in absorption linked to the formation of structural defects, particularly oxygen vacancies. Finally, the optical band gap (Eg) decreases from 4.14 eV to 2.5 eV after crystallization, due to the creation of intermediate states in the band gap.

In conclusion, this study shows that an optimal compromise between high refractive index, low optical loss, and a wide transparency window can be achieved by controlling the amorphous or crystalline phase of the layers. Amorphous layers have a refractive index of 2.15 and an extended relative transparency window (1.55–4.5 eV), while crystalline layers offer a higher refractive index (2.24) but reduced transparency due to sub-bandgap absorption. These results open up prospects for advanced optical applications, such as interference filters, nonlinear waveguides, or photonic metamaterials, and suggest that the next step is to optimize annealing conditions to minimize structural defects and further improve optical performance.

Optical performance of high refractive-index transparent Ta2O5: Relative Transparency window size Esize as a function of refractive index n. The grey dashed region represents crystallized films, while pink region corresponds to amorphous films. Arrows reflect the processing steps (growth conditions and annealing process).

Reference:

Tailoring structural and optical properties of Ta2O5 thin films via radio frequency magnetron sputtering for high-refractive index transparent materials,

Aïmane Cheikh, Jeremie Gonçalves, Christophe Labbé, Xavier Portier, Philippe Marie, Cedric Frilay, Olivier Debieu, Sylvain Duprey, Wojciech Jadwisienczak, David Ingram, Julien Cardin, Journal of Alloys Compounds, 1040, 183273 (2025).

(Data base refractive index.info)

Contact CEA: Julien Cardin, IRAMIS/CIMAP/NIMPh

Collaboration:

- Centre interuniversitaire de recherche et d’ingénierie des matériaux – CIRIMAT (UMR CNRS, Université Toulouse, Toulouse INP), France.

- Nanoscale & Quantum Phenomena Institute – NQPI, Ohio University, USA.