Photocurable denture bases require both rigidity (high flexural strength and modulus) and high fracture toughness (to prevent cracking or breaking under mechanical stress).

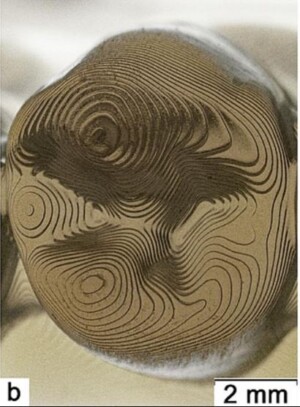

These antagonist properties can be provided by the incorporation of block copolymers (BCPs) due to their unique self-assembly properties conferring an overall improvement of fracture toughness and mechanical properties to denture base materials. In the present work, it was shown that poly(methyl methacrylate)-block-poly(dimethyl siloxane)-block-poly(methyl methacrylate) (PMMA-PDMS-PMMA) triblock copolymers are highly efficient toughening agents for (meth)acrylic resins, resulting in a significantly improved fracture toughness without compromising the mechanical strength or processing. The influence of the PMMA:PDMS block ratio and the weight fraction of triblock copolymer (3-10 wt %) in the resin was investigated and revealed that the most efficient toughening triblock copolymer is composed of PMMA and PDMS blocks having the similar molecular weight of 8000 g mol-1. The highest fracture toughness value (Kmax = 2,25 MPa m1/2) was obtained with this BCP at a concentration of 5 wt% in the resin, an improvement of 180 % compared to the BCP free resin. Small angle X-ray scattering measurements revealed that self-assembly of BCPs led to the formation of spherical micelles that transform to small clusters after curing if the compatible PMMA block is sufficiently long compared to the incompatible PDMS block. Otherwise, large aggregates were observed. Transmission electron microscopy confirmed the SAXS results, showing the clusters of spherical micelles. As toughening agents, PMMA-PDMS-PMMA BCPs showed better performance than the reference polycaprolactone-polysiloxane (PCL-PDMS-PCL) one. The influence of the nature of the compatible block (PMMA versus PCL) and of the PMMA:PDMS block ratio on the fracture toughness of radical-cured resin systems was clearly demonstrated in this study. The most promising formulation was shown to be suitable for digital light processing 3D printing.

Hien The Ho, Kai Rist, Iris Lamparth, Sadini Omeragic, Pascal Fässler, Fabrice Cousin, Loïc Vidal, Jacques Lalevée, Didier Gigmes, Yohann Catel, Trang N.T. Phan