Secondary ion mass spectroscopy – SIMS – is a highly sensitive chemical analysis technique, based on the mass analysis of secondary ions emitted following ion bombardment of the sample. The primary ion source should ideally be bright, with good ionization efficiency and good lateral resolution, to enable high-resolution imaging, and the primary ions should have a high resolution. Liquid metal ion sources (LMIS) are bright, with a resolution of 2.5 nm, but their efficiency is much lower than that of O- or Cs+ ion sources. A source combining all three advantages would enable high-resolution SIMS imaging, with much faster acquisition times than with current sources.

Within the framework of the CICLOP joint laboratory, bringing together the CIMAP laboratory and Orsay Physics, the proof-of-concept for a high-performance capillary source based on molten salt enriched with cesium and oxygen has been developed. Obtaining a beam of positive Cs+ ions, stable over 50 min, and the negative polarity of a beam of NO3–, is promising for the development of a prototype universal source for SIMS applications.

For secondary ion mass spectroscopy (SIMS), the primary ion source should ideally be bright, have good lateral resolution for high-resolution imaging, and the primary ions should have good ionization efficiency. Sources based on O– and Cs+ ions have the required ionization yields (10-3 – 10-2 ion sec. /ion prim.), but their lateral resolution is limited to typically 500 nm. In contrast, liquid gallium-based sources (LMIS) are bright, with a resolution of 2.5 nm, but a yield typically 100 times lower than oxygen and cesium. Developing a source combining all three advantages would enable high-resolution imaging for SIMS analysis, with a scan speed 100 times faster than an LMIS source.

As part of the CICLOP joint laboratory between CIMAP and Orsay Physics, the proof-of-concept for a molten-salt-based ion source for SIMS has been developed [1]. To maximize the ionization yield of primary ions, the source uses a nitrate salt, a mixture of CsNO3 (53% mol.) and LiNO3 (47% mol.), enriched in cesium and oxygen. The eutectic mixture enables a low melting point of 134°C to be achieved under vacuum.

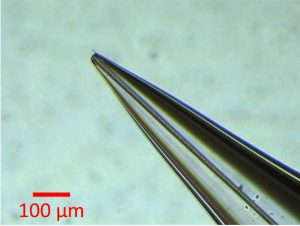

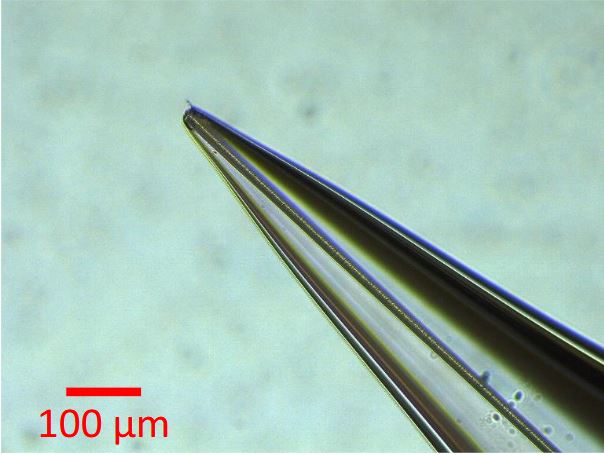

This salt is inserted into a borosilicate capillary with a conical tip and a hole a few micrometers wide, and the capillary is heated to melt the salt. As the molten salt (SF) does not wet the borosilicate glass, it does not spontaneously fill the tip of the capillary. Applying a simple 300 mbar overpressure is enough to push the molten salt to the tip orifice, but this process does not achieve equilibrium and the capillary quickly empties. As the molten salt wets the alumina, an alumina fiber is inserted into the capillary tip to regulate the outflow. Its diameter is adjusted to the inside diameter of the tip. A slight overpressure of 30 mbar of nitrogen is then sufficient to carry the salt to the tip.

Under the effect of an electric field, the conductive liquid present at the tip orifice deforms into a Taylor cone, from which ions are emitted. Like an LMIS, the radius of curvature of the conical meniscus is around one hundred nanometers, enabling a bright beam to be generated with good lateral resolution of a few nm. As part of Massimo Léger’s thesis work, a beam of Cs+ ions stable for 50 min and a beam of NO3– in negative polarity were produced with this type of source.

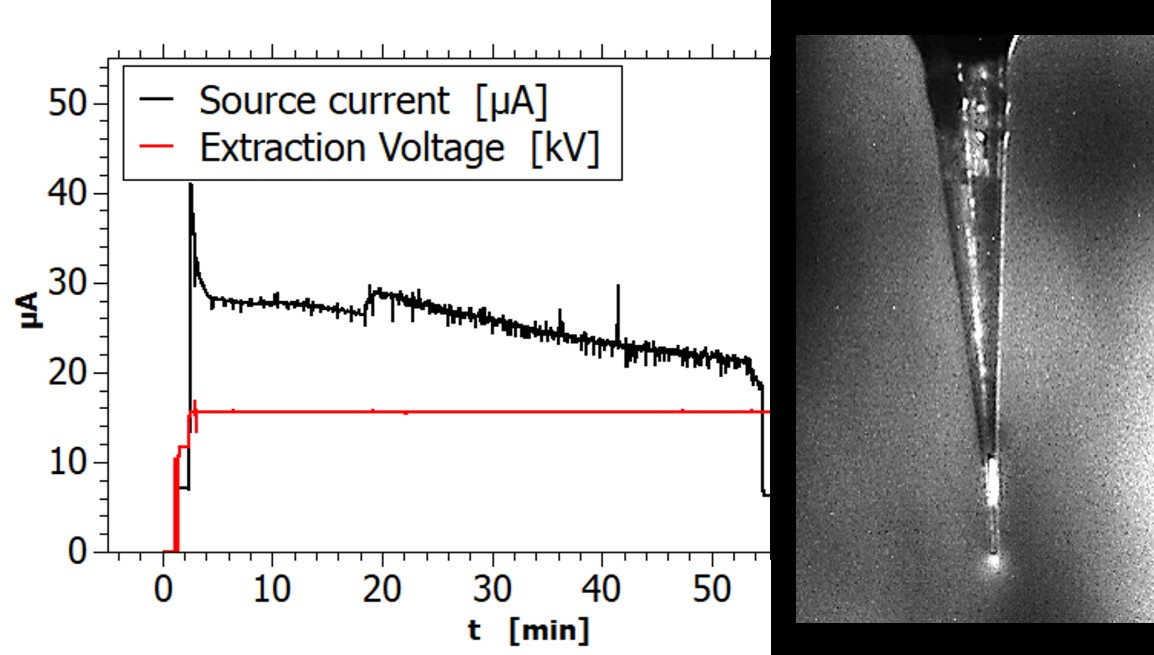

Right: image of borosilicate capillary tip with the plasma glow at the end of the capillary. Left: emitted ion current (black curve) and extraction voltage (red curve) versus time.

The figure on the right shows the end of the SF-filled capillary, with the plasma glow at its tip, indicating ion emission. The alumina fiber inside the capillary is not visible in the figure. The intensity of the ion beam (black curve) as a function of time is shown on the left of the figure. The current decay observed, followed by the shutdown after 50 minutes of operation, are the result of the decreasing overpressure applied to the molten salt.

These initial results are very promising for the development of a prototype universal source for SIMS applications. As a next step, it is proposed to improve the wettability of the glass by the molten salt via a treatment of the inner surface of the capillary, which should eliminate any overpressure on the molten salt and thus improve the stability and durability of the source.

Reference:

[1] “Molten salt ion source using glass capillaries as emitter “, M. Léger, E. Giglio, S. Guillous et A. Houel, submitted to Journal of vacuum science and technology B, ArXiv:2412.09374v1

Contact CEA-IRAMIS: Eric Giglio, Équipe SIMUL du CIMAP.

Collaboration:

- Arnaud Houel, Orsay Physics, TESCAN Group, F-13710 Fuveau, France