Jacques Jestin, Nicolas Jouault, Chloé Chevigny, François Boué, Laboratoire Léon Brillouin, CEA Saclay

One way to strengthen the mechanical properties of plastic materials is to add nanoparticles, forming that way a composite material. A detailed structural study by neutron scattering, coupled with mechanical tests, of polystyrene reinforced with silica particles has been performed at the Laboratoire Léon Brillouin (LLB) at CEA Saclay. It shows the importance to control the concentration and distribution of particles entering in the composition of the material. This model study has many applications, especially in the tire technological domain.

Plastics are made of molecules or entangled polymers, that may be soft / slimy, hard / brittle or deformable (rubber, …). These materials have a wide range of mechanical (reinforcement, adhesion, tensile strength), thermal (insulation), electrical (conductivity), or optical (color) properties, allowing applications in various industries such as tires, paints, oil or food packaging …

These remarkable properties can be improved by inclusion of particles inside the material to form a nanocomposite. The particles must be as small as possible (“nanoparticles” : 1 nanometer = 10-9 m): at this scale, the specific particle-particle and particle-polymer interactions will allow the creation of new distribution of the particle load (dispersion of independent particles, clusters (aggregates) or a connected network). In addition, the higher affinity between the polymer and the particles leads to new macroscopic properties of the materials. The classical mechanical models, which do not include these specific contributions, are struggling to adequately describe the mechanical behavior of such nanocomposites. Therefore, model systems are necessary to separate the contribution of each component (particles and polymer chains), to the mechanical response of the material.

Our model systems are composed of silica nanoparticles dispersed in a matrix of polystyrene. Depending on the concentration, the particles may be dispersed as small clusters that are not interconnected, or at higher concentration may form a continuous network.

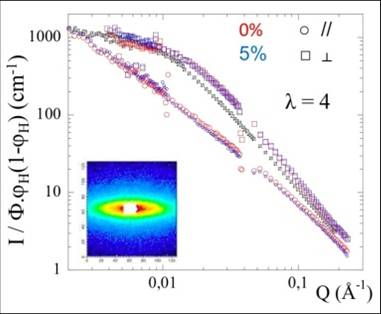

To determine their atomic structure, the samples were studied by neutron diffraction within the Léon Brillouin Laboratory. By neutron diffraction at small scattering angles, the organization of matter over large distances can be deduced giving access to the distribution of the nanoparticles. Specifically with neutron scattering, the investigation of a mixture of hydrogenated and deuterated chains, allows determining determining the location and shape (conformation) of the polymer chains.

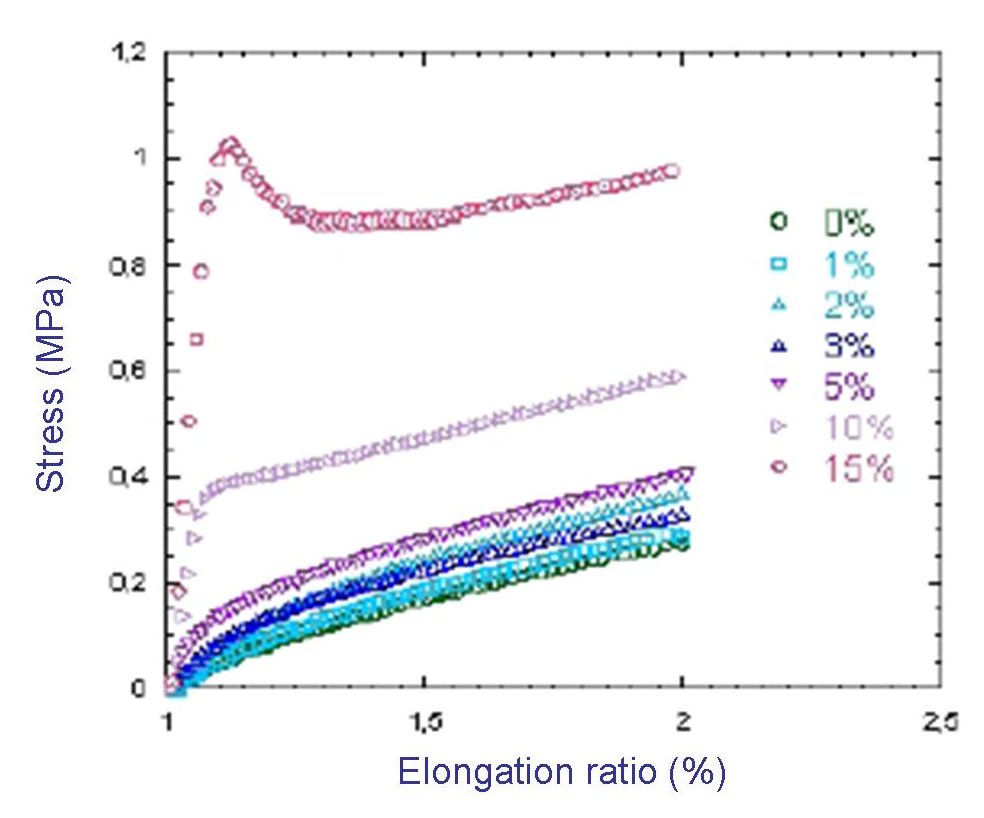

In parallel to structural studies by neutron scattering, the mechanical properties of the material were studied. At the threshold of connectivity for the particles, a divergence of the mechanical reinforcement factor (ratio of elastic moduli with and without silica filler) is observed. This shows the direct correlation between the nanoscale structure and the macroscopic mechanical response the material. In parallel, the average conformation of polymer chains is also determined by neutron scattering. It is shown that this conformation is not affected by the presence of particles. Thus, the deformation of the chains does not contribute to the strengthening of the material.

The grafting of small polymer chains to the particles provides an additional way of controlling the dispersion of particles in the matrix. Depending on the organization of particles (aggregated or dispersed), the grafted chains (observed by neutron scattering) are more or less compressed. The strengthening mechanism is reduced in this case because of deformation of the grafted chains at the interfaces with the particles.

In conclusion, this study shows the correlation between the distribution of a load of nanoparticles and the mechanical reinforcement of a plastic material. For a better reinforcement, the nanoparticles must be dispersed at high enough concentration to be connected. A better control of the dispersion of the load by polymer grafting onto the silica particles reduce, however, the mechanical reinforcement.

References:

Direct small-angle-neutron-scattering observation of stretched chain conformation in nanocomposites: More insight on polymer contributions in mechanical reinforcement,

N. Jouault, F. Dalmas, S. Said, E. Di Cola, R. Schweins, J. Jestin, F. Boué,

Physical Review E, 82 (3), 031801, 2010.

Direct Measurement of Polymer Chain Conformation in Well-Controlled Model Nanocomposites by Combining SANS and SAXS,

N. Jouault, F. Dalmas, S. Said, E. Di-Cola, R. Schweins, J. Jestin, F. Boué,

Macromolecules, 43(23) (2010) 9881.

Controlled grafting of polystyrene on silica nanoparticles using NMP: a new route without free initiator to tune the grafted chain length,

C. Chevigny, D. Gigmes, D. Bertin, R. Schweins, J. Jestin, F. Boué,

Polymer Chemistry, 2 (2011) 567.

Polymer-grafted-nanoparticles nanocomposites: dispersion, grafted chain conformation, and rheological behavior,

C. Chevigny, F. Dalmas, E. Di Cola, D. Gigmes, D. Bertin, F. Boué, J. Jestin,

Macromolecules, 44(1) (2011) 122.

Tuning the mechanical properties in model nanocomposites: Influence of the polymer-filler interfacial interactions,

C. Chevigny, N. Jouault, F. Dalmas, F. Boué, J. Jestin,

Journal of Polymer Science Part B: Polymer Physics (2011).

Contact: Jacques Jestin.