The rapid evolution of electronic technologies has intensified the environmental challenges associated with electronic waste containing precious and often essential or critical metals, such as silver (Ag). Efficient recovery of Ag from waste streams with highly variable compositions is therefore crucial to mitigate environmental impacts and promote a circular economy, as silver is present in the vast majority of electronic components due to its favorable electrical properties.

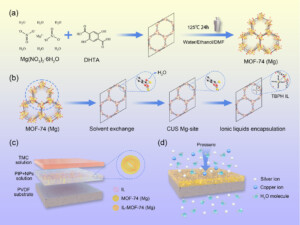

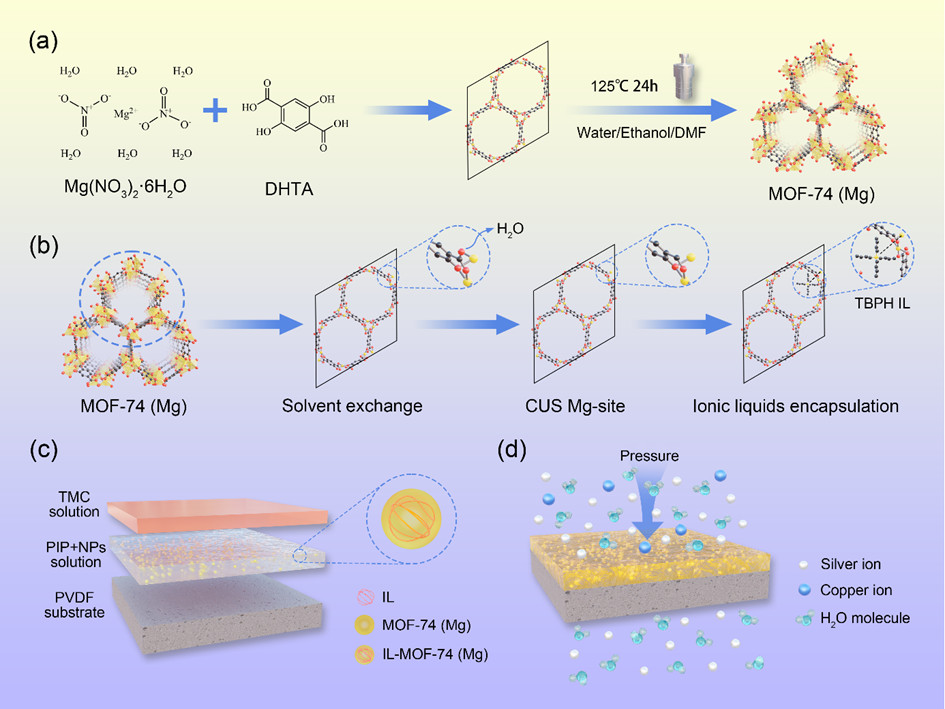

In previous work, we demonstrated that the encapsulation of ionic liquids (ILs) within a metal-organic framework (MOF) porous network, mechanically stabilized by a polymeric binder, could overcome several technical limitations of supported liquid membranes (SLMs)*, such as mechanical instability and IL leakage or detachment. This strategy also enabled the design of “tailor-made” porosity, adaptable to the targeted ion. This first proof of concept was demonstrated for lithium separation [1].

Additional advantages of this composite architecture include the ability to exploit the high porosity and hydraulic stability of MOFs. Furthermore, certain MOFs can be selected to feature unsaturated coordination sites, i.e., sites capable of forming additional chemical bonds with specific elements or molecules, thereby enhancing the overall performance of the membranes. Building on these results, we proposed a second formulation of these IL-MOF thin-film nanocomposite (TFN) membranes, providing enhanced selectivity toward silver, particularly over copper, as well as improved stability and efficiency (up to 99.4%) when applied to solutions derived from the recycling of ceramic capacitors [2].

Following this success, we investigated the possibility of reducing the cost of MOF synthesis, notably by using an electronic-waste leaching solution (lixiviate) as the reaction medium for MOF synthesis. As these solutions are typically rich in copper, we targeted the synthesis of a bimetallic copper/silver MOF, whose formation tolerates variability in the Cu/Ag ratio. Membranes fabricated from this MOF exhibited high specificity toward silver and enabled the recovery of more than 99% of the dissolved silver [3].

*This type of membrane relies on a very thin liquid film confined within a porous material, which acts as the exchange/filtration zone between two compartments.

This work, carried out within the CEA/NTU joint laboratory in Singapore, highlights a synergistic approach that combines the unique properties of ionic liquids and MOFs to develop sustainable and high-performance solutions for metal recovery applications.

References

[1] « Tailorable metal-organic framework based thin film nanocomposite membrane for lithium recovery from wasted batteries » Bo Han, Sarah M. Chevrier, Qingyu Yan, Jean-Christophe P. Gabriel, Separation and Purification Technology, 2023.

[2] « Enhanced Silver Recovery from Electronic Wastes Using Ionic Liquid-Integrated Nanocomposite Membrane. » Bo Han, Ziyang Liu, Dong Xia, Guillaume Zante, Qingyu Yan, Jean-Christophe P. Gabriel, Separation and Purification Technology, 2025.

[3] « From electronic wastes to efficient and specific filtration membranes: A photovoltaic upcycling case enabling silver urban mining. » Bo Han, Ying Sim, Qingyu Yan, Nripan Mathews, Jean-Christophe P. Gabriel, Journal of Cleaner Production, 2025.

Collaboration

- Commun laboratory CEA/NTU SCARCE, Nanyang Technological University Building CCEB N1.2, 62 Nanyang Dr, Singapore 637459, Singapore.

- LICSEN, NIMBE, UMR 3685, CEA-Saclay, CEA-CNRS, 91191 Gif-sur-Yvette Cedex, France.

Contact CEA

Jean-Christophe Gabriel, NIMBE – Nanosciences et Innovation pour les Matériaux, la Biomédecine et l’Énergie, LICSEN – Laboratoire Innovation, Chimie des Surfaces Et Nanosciences, CEA-IRAMIS.