This area of LAPA research deals with understanding the degradation of systems under the effect of very long-term corrosion (for periods generally exceeding a century). These studies provide crucial data for the very long-term modelling and protection of materials and have several areas of application: the main one is the prediction of corrosion and alteration over multi-century periods of the metallic materials used in the multibarrier for storage and disposal of nuclear wastes. Studies are being carried out both on archaeological systems considered as analogues, and on laboratory experiments (notably in close collaboration with Andra), which are currently reaching ten years in terms of weathering time.

Research is also focusing on the corrosion processes of archaeological metal objects themselves, in order to gain a better understanding of the states of alteration and the parameters that determine corrosion kinetics. The fields of application here are preventive conservation, particularly on site but also in museum storage rooms. The environments considered are more varied than for corrosion studies in the nuclear sector: aerated or non-aerated soils, in or outdoor atmosphere and marine environment, for example.

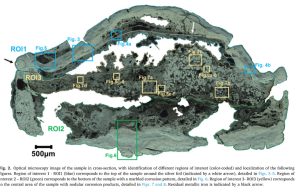

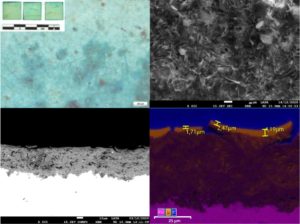

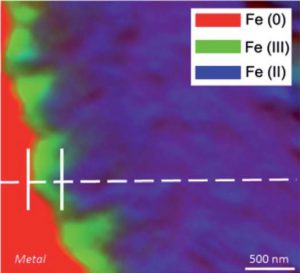

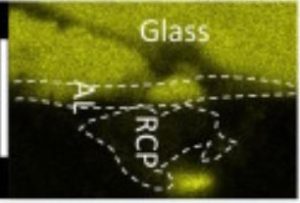

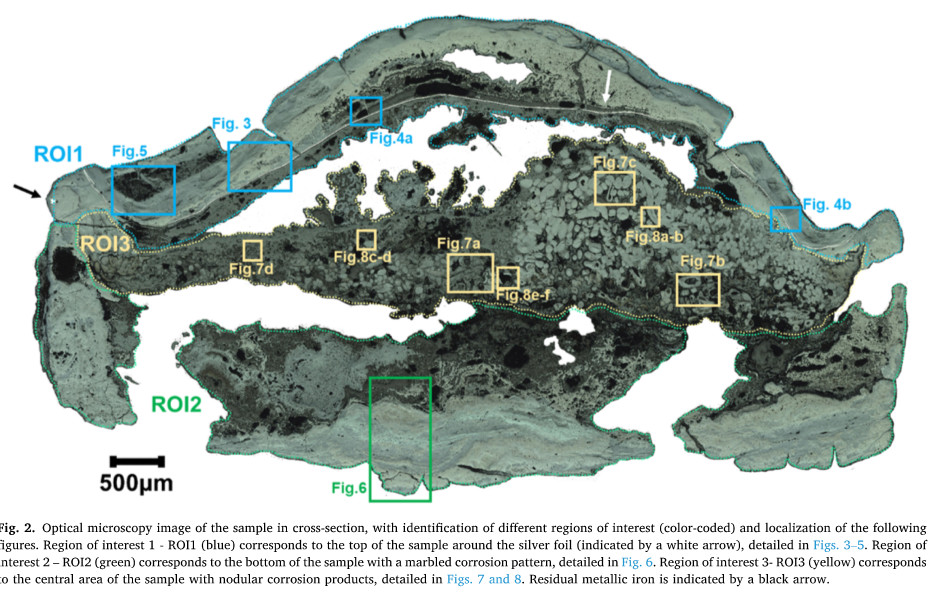

Cross-section of a Roman ring. Valbi et al, 2024