Contact CEA : Pascal Boulanger

A decade after their first synthesis in the laboratory, carpets of aligned carbon nanotubes (CNTs) are being considered in many fields of applications (filtration membranes, passive and active electronic components, composite materials,..) combining CNTs’ individual properties and nano-structuration. But the development of these applications requires a safe, inexpensive process that is applicable over large areas. In this technological approach, the “Edifices nanométriques” (EDNA) group of IRAMIS/SPAM/Laboratoire Francis Perrin has taken an important step in controlling the production of large surfaces, carpets of aligned CNTs with high quality and controllable properties as well as high homogeneity. This is the result of an effort to support basic research for several years by the pioneering team, towards a better understanding of the mechanisms of growth of such nanostructures and thus to control the process.

Carbon nanotubes (CNTs) are the focus of intense research activity since its identification in 1991 by S. Iijima and mobilize both research and industry. Intended applications are numerous (composite materials, sensors, interconnections, generator, energy conversion and storage, filtration membranes, etc …) and impact a variety of fields such as electronics, automotive, military, aerospace,, energy, medical, environment, … Today, CNTs can be manufactured in large quantities but only in powder form in which they are entangled each other. This dispersed arrangement of CNTs requires while their manipulation, delicate and difficult stages such as dispersion, sorting or mixing.

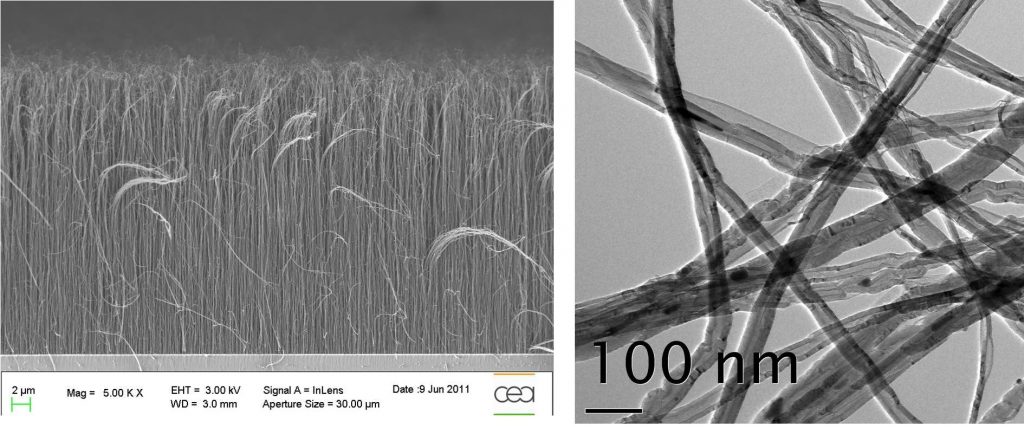

The first vertically aligned CNTs with the image of a carpet brushes were synthesized by CVD (Chemical Vapor Deposition) in the laboratory in 1998. This organization of aligned CNTs can better exploit the CNT’s unidirectional properties and facilitate their layout, which paves the way for new applications. With the development of CVD processes, much progress has been made in synthetizing vertically aligned CNTs, and today it is possible to grow multi-walled as well as single-walled CNTs on different substrates with a high quality and well-defined characteristics. However, the implementation of these processes for the realization of CNTs carpets over larger areas has, so far, only been achieved in 2009 through the implementation process consisting of a two-steps process: controlled preparation of the substrate, prior to the synthesis of nanotubes, making it an expensive and difficult process to implement for mass production.

In this context, one of the objectives of the CEA, is to develop secure and inexpensive processes to produce, in a single-step, vertically aligned CNTs carpets with well-controlled features, over large areas. This would allow the designing and shaping of advanced materials integrating vertically aligned CNTs and especially their evaluation under realistic conditions of manufacture and use.

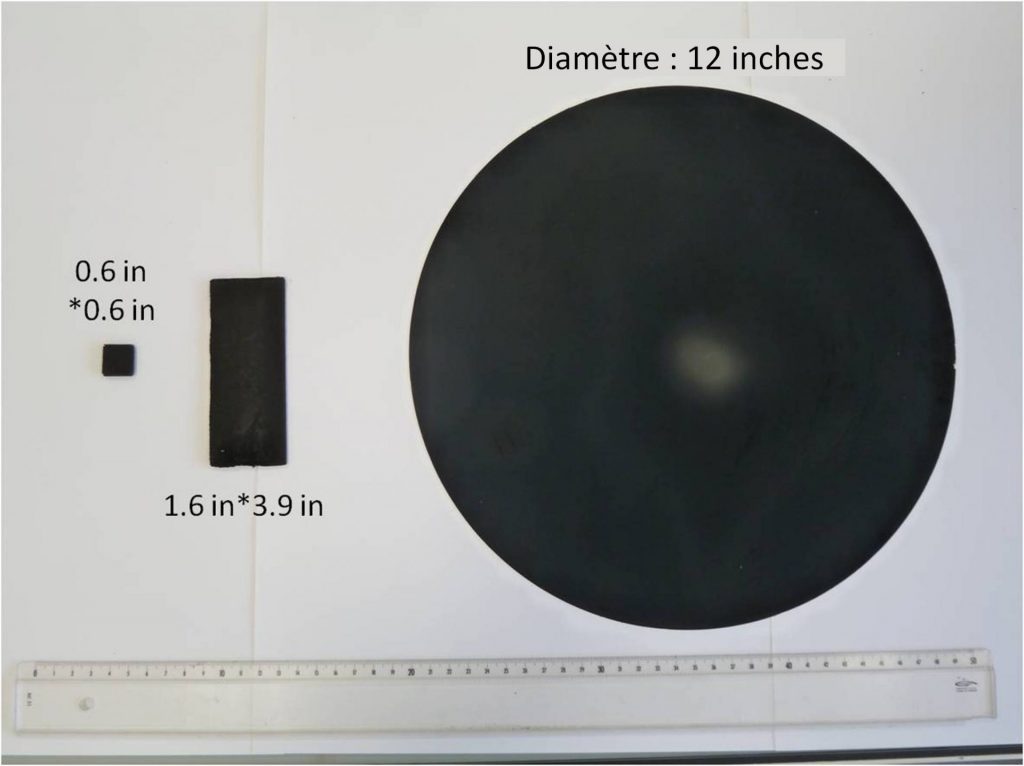

Based on his knowledge and mastery of CVD processes, the EDNA (Edifices nanométrique) group of IRAMIS/SPAM/Laboratoire Francis Perrin has succeeded the synthesis vertically aligned CNTs carpets on a 30 cm in diameter silicon wafer. It is now possible to produce continuously and in one-step, vertically aligned CNTs carpets over large surface areas, thus removing the first locks of their industrialization.

During ten years of fundamental research, the group developed an original synthetis process of vertically aligned CNTs carpets in a single-step process by aerosol assisted CVD. This manufacturing technique allows to grow carpets continuously, at atmospheric pressure and under secure conditions of use of chemicals (precursors and carbon sources) [1]. This method is known inexpensive for industrial manufacturing thin films. The understanding of the growth mechanisms [2, 3] allows producing a wide range of carpets while controlling their properties (in diameter, density, length shape and doping). This has been a milestone in 2005 [5]. These nanotubes are essentially “multi-walled”, but can be synthesized on various substrates (flat, curved or flexible) with a end-less and very high growth rate (up to 60 microns/min).

This result also demonstrates that control growth conditions performed on small areas furnaces could be extended to larger areas, leading to homogeneous carpets, while maintaining the same opportunities for process control. This result was obtained in both the framework of a European project (SAPHIR) and an ANR Nano-Innov-RT (NaWaA4), in which a new pilot reactor was designed by the team.

Ce résultat est unique dans la mesure où les premières synthèses de tapis de nanotubes sur grandes surfaces réalisées depuis 2009 utilisent une technique de CVD en deux étapes plus proches de l’industrie micro-électronique et plus chère, alors que la technique CVD d’aérosol relève des techniques de CVD classique en une seule étape utilisant des précurseurs organo-métalliques.

This result is unique in that it’s the first vertically aligned CNTs carpets synthesis on such a large area made since 2009, using the aerosol assisted CVD technique that can lead to cheaper applications.

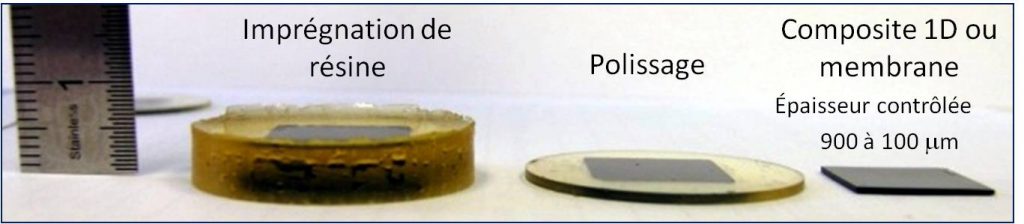

This result, under publication, is paving the way for prototyping of new materials on a scale never before possible. The EDNA group will continue its researches on the growth process to further extend the range of morphological and dimensional control fo vertically aligned CNTs carpets, as well as the shaping of advanced materials incorporating these carpets in an integrated, safe, economical and high efficiency process,. Realizations of multifunctional composite materials such as sensors, electrodes or membranes [4] are some of the applications targeted in the field of energy and environment.

Références :

[1] Growth of multiwalled carbon nanotubes during the initial stages of aerosol-assisted CCVD

M. Pinault, M. Mayne-L’Hermite, C. Reynaud, V. Pichot, P. Launois and D. Ballutaud, Carbon 43, 2968, (2005)

[2] Evidence of sequential lift in growth of aligned multi-walled carbon nanotube multilayers

M. Pinault, V. Pichot, H. Khodja, P. Launois, C. Reynaud and M. Mayne-L’Hermite, Nano Lett. 5 (12), 2394, (2005).

[3] Dynamics of catalyst particle formation and multiwall carbon nanotube growth in aerosol-assisted catalytic chemical vapor deposition

C. Castro; M. Pinault; S. Coste-Leconte; D. Porterat; N. Bendiab; C. Reynaud; M. Mayne-L'Hermite, Carbon 48, (2010) 3807-3816.

[4] Upscaling fabrication of aligned carbon nanotube membranes : opportunities and challenges

P. Boulanger, L. Belkadi, A. Brouzes, N. Dinter, M. Mille, M. Pinault, E. Hibert, C. Reynaud, M. Mayne-L’Hermite,,

Int. Cong ICOM2011, Amsterdam, July 2011.

[5] IRAMIS highlight 2005 : Identification du mode de croissance de multi-couches de nanotubes de carbone alignés.

[6] Scaling up high yield aerosol assisted CCVD synthesis of vertically aligned CNTs carpets,

L. Belkadi, E. Hibert, S. Patel, D. Porterat, M. Pinault, P. Boulanger, M. Mayne, C. Reynaud, to be published.

Contact CEA : Pascal Boulanger (IRAMIS/SPAM/EDNA).

The EDNA group wants to acknowledge for their financial support: