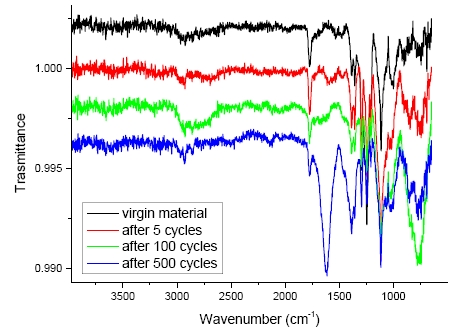

Fig. 1 : Variation of the friction coefficient during the simulation of an electrical contact life, protected or not with different kinds of films (poly(heptafluorobutylmethacrylate) charged or not with nanotubes)

We study electro-grafted films on metal substrates as a solution for the dry lubrication of low-level electric contacts. At the moment low-level electric contacts are lubricated by means of liquids lubricants but this solution is not satisfactory for many reasons and electrical contacts still remain the weakest point of electrical circuits and a main source of failure. Among the degradation phenomena that occur in traditional liquid lubricated electrical contacts are oxidation, wear, overheating and fretting (oxidation and premature wear caused by mechanical vibrations). Many of those phenomena are caused by liquid lubricants displacement or its degradation, leading to unprotected metal-to-metal contacts.

Moreover with the increasing miniaturization of device components and high-performance materials, the surface-to-volume ratio increases, and the properties of the surfaces become increasingly more important. In many cases, especially in aerospace, high-temperature, and computer applications, it is also impractical or undesirable to have a liquid lubricant present, and one has to rely entirely on the tribological properties of dry surfaces.Therefore the functionalization of metallic surfaces with organic molecules to impart “lubricating” properties becomes a subject of major interest both from fundamental and technological points of view.

With respect to other techniques for grafting organic molecules on metal surfaces (SAM, Langmuir-Blodgett films, …) electrografting allows the formation of strong covalent bonds at the organic/inorganic interface leading to the formation of highly-adherent thin-films (thickness < 50nm). The electrografting of fluorinated molecules (fluorinated diazonium salts or fluorinated methacrylates) allows obtaining robust films providing low-friction properties.

As those films are naturally insulating, the necessary electrical transport through the metal-organic-metal interface can be borne by adding a conducting or semi conducting charge to the films. In particular we concentrate on carbon nanotubes networks and on conducting fluorinated PEDOT.

Our early results on grafted fluorinated polymethacrylates films show excellent behaviour in term of stability and tribological properties, reaching friction coefficient as low as 0.1 and showing wear resistance in severe testing conditions. (Fig. 1).

The addition of carbon nanotubes to the fluorinated films actually reduces the contact electrical resistance, in same cases of a decade. More work is in progress to reach higher conductivities.

As stated above, research on the tribology on grafted organic molecules as boundary lubricants have also an interest from the fundamental point of view. Results are expected to reduce the gap between friction theoretical models on ideal surfaces and experiments. For this reason experiments are also conducted on the nanometer scale with AFM, in order to associate nanoscopic properties to macroscopic behaviour.

The effect of friction on the modification of the chemical structure of the organic films is studied after the tribological tests to delineate the pathways of chemical reactions under mechanical stress and high temperatures. The following picture (Fig. 2) shows the modification of Infra-Red absorptions bands of a protective organic film at different stages during the simulated life of an electrical contacts.

Contact:

References :

(1) Noel, S.; Alamarguy, D.; Houzé, F.; Benedetto, A.; Viel, P.; Palacin, S.; Izard, N.; Chenevier, P.; Nanocomposite thin films for surface protection in electrical contact applications ; IEEE Trans. Comp. Packa. Tech. 2009, 32, 358-364.

(2) Benedetto, A.; Balog, M.; Rayah, H.; Le Derf, F.; Viel, P.; Palacin, S.; Sallé, M.; Electro-reduction of diazonium salts on gold: why do we observe multi-peaks ?; Electrochimica Acta 2008, 53, 3779-3788.

(3) Alamarguy, D.; Benedetto, A.; Balog, M.; Noël, S.; Viel, P.; Le Derf, F.; Houzé, F.; Sallé, M.; Palacin, S.; Tribological and electrical study of Fluorinated Diazonium Films as dry lubricants for electrical contacts; Surface and Interface Analysis 2008, 40, 802-805.

(4) Benedetto, A.; Balog, M.; Rayah, H.; Le Derf, F.; Viel, P.; Palacin, S.; Sallé, M.; Fluorinated functionnalized EDOT-based conducting films; Electrochimica Acta 2008, 53, 3779-3788.

(5) Benedetto, A.; Viel, P.; Noël, S.; Palacin, S.; Izard, N.; Chenevier, P.; Carbon nanotubes/fluorinated polymers nanocomposite thin films for electrical contacts lubrication; Surface Science 2007, 601, 3687.

•  Synthèse et caractérisation des nano-objets / Synthesis and characterization of nano-objects › From molecules to molecular materials

Synthèse et caractérisation des nano-objets / Synthesis and characterization of nano-objects › From molecules to molecular materials

•  Institut Rayonnement Matière de Saclay • Laboratory of Physics and Chemistry of Surfaces and Interfaces • UMR 3685 NIMBE : Nanosciences et Innovation pour les Matériaux, la Biomédecine et l'Énergie • Service de Physique et Chimie des Surfaces et des Interfaces

Institut Rayonnement Matière de Saclay • Laboratory of Physics and Chemistry of Surfaces and Interfaces • UMR 3685 NIMBE : Nanosciences et Innovation pour les Matériaux, la Biomédecine et l'Énergie • Service de Physique et Chimie des Surfaces et des Interfaces

• Laboratory of Chemistry of Surfaces and Interfaces (LCSI) • Laboratoire d'Innovation en Chimie des Surfaces et Nanosciences (LICSEN) • Laboratoire Innovation, Chimie des Surfaces Et Nanosciences- LCSI (LICSEN-LCSI)