1) Modeling the dynamics of structuration of a porous organic membrane - application to water treatment

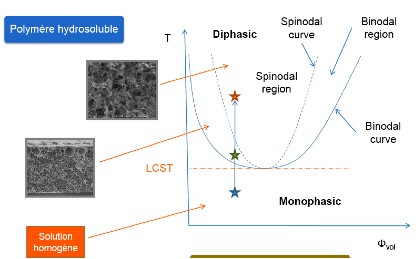

The porous organic membranes are developed by a demixing system polymer / solvent (or polymer / solvent / non-solvent) inducing the formation of a phase rich in polymer (membrane) around a phase very dilute in polymer (the pores after removal of solvent). The basic mechanisms that control the formation of pores are still only partially understood and rarely perfectly controlled. On an industrial scale, membrane manufacturing is mostly done through trial and error loops, the operating parameters being adjusted gradually and empirically. The formalization of the mechanisms through systemic models is even less developed, although it allows to slide towards a more rational and predictive of the development.

The aim of the thesis is to improve understanding of the mechanisms of phase separation by spinodal decomposition, in order to better control the formation of porous organic membranes. A modeling approach will be coupled with an experimental approach to complete this project.

Beyond the fundamental nature of the project, it fits into a broader context of wastewater reuse (irrigation, watering public ...) that requires the use of innovative membranes for controlled selectivity: the retention of small organic molecules -resistant membranes requires that the distribution of pore sizes is perfectly controlled.

Phase separation by spinodal decomposition phenomenon is described by the Cahn-Hilliard equation [1-4]. Although its expression is relatively simple, its resolution is complex because it incorporates many parameters. To simplify the modeling, the first phase of work will be to choose a process of phase separation and a relatively simple system polymer / solvent model. In this context, the TIPS process-UCST (Upper Critical Solution Temperature) will be retained because it was the subject of many studies and scientific literature is abundant about it [5]. It is based on a phase separation induced by a decrease in temperature and allows to work with a binary polymer / solvent. The results of numerical simulation will be compared with experimental measurements by light scattering and / or light microscopy according to the size of structures.

A second step, given the experimental results, refine the original model proposed by Cahn and Hilliard. Two improvements will be tested: the first will include a more complete description of diffusion phenomena considering the fact that the representation of Flory-Huggins free energy of polymer-solvent mixture is often inaccurate, especially for water soluble polymers . The second enhancement is to describe more accurately the convective and the couplings involved in the viscoelastic phase separation through the velocity field [4]. The numerical simulation model of phase separation will be done via the computer code COMSOL Multiphysics ®, which allows the resolution of partial differential equations by the finite element method. Model validation will be done through studies of light scattering at small angles that can record the time evolution of the structure factor, to ultimately obtain information on the evolution of the characteristic size of the structure that separates [6]. When the size becomes too large for the light scattering to be possible, a study by light microscopy and image processing will be undertaken.

[1] Cahn J.W. and J. E. Hilliard, Free energy of nonuniform system. I. Interfacial free energy, J. Chem. Phy. 28 (1957) 795.

[2] Leea K-W. D., P. K. Chanb, X. Feng, Morphology development and characterization of the phase-separated structure resulting from the thermal-induced phase separation phenomenon in polymer solutions under a temperature gradient, Chem. Eng. Sci. 59 (2004) 1491

[3] Zhou B., A. C. Powell, Phase field simulations of early stage structure formation during immersion precipitation of polymeric membranes in 2D and 3D, J. Membr. Sci. 268 (2006) 150

[4] Tanaka H., T. Araki, Viscoelastic phase separation in soft matter: Numerical-simulation study on its physical mechanism, Chem. Eng. Sci. 61 (2006) 2108

[5] Li D., W. B. Krantz, A. R. Greenberg, R. L. Sani, Membrane formation via thermally induced phase separation (TIPS): Model development and validation, J. Membr. Sci. 279 (2006) 50

[6] Lacaze, M.; Guenoun, P. ; Beysens D. ; Delsanti M. ; Petitjeans P. ; Kurowski P. Transient surface tension in miscible fluids. Phys. Rev. E, 82 (2010) 041606.

2) Nanoimprint: Towards ordered nanostructures with large aspect ratio

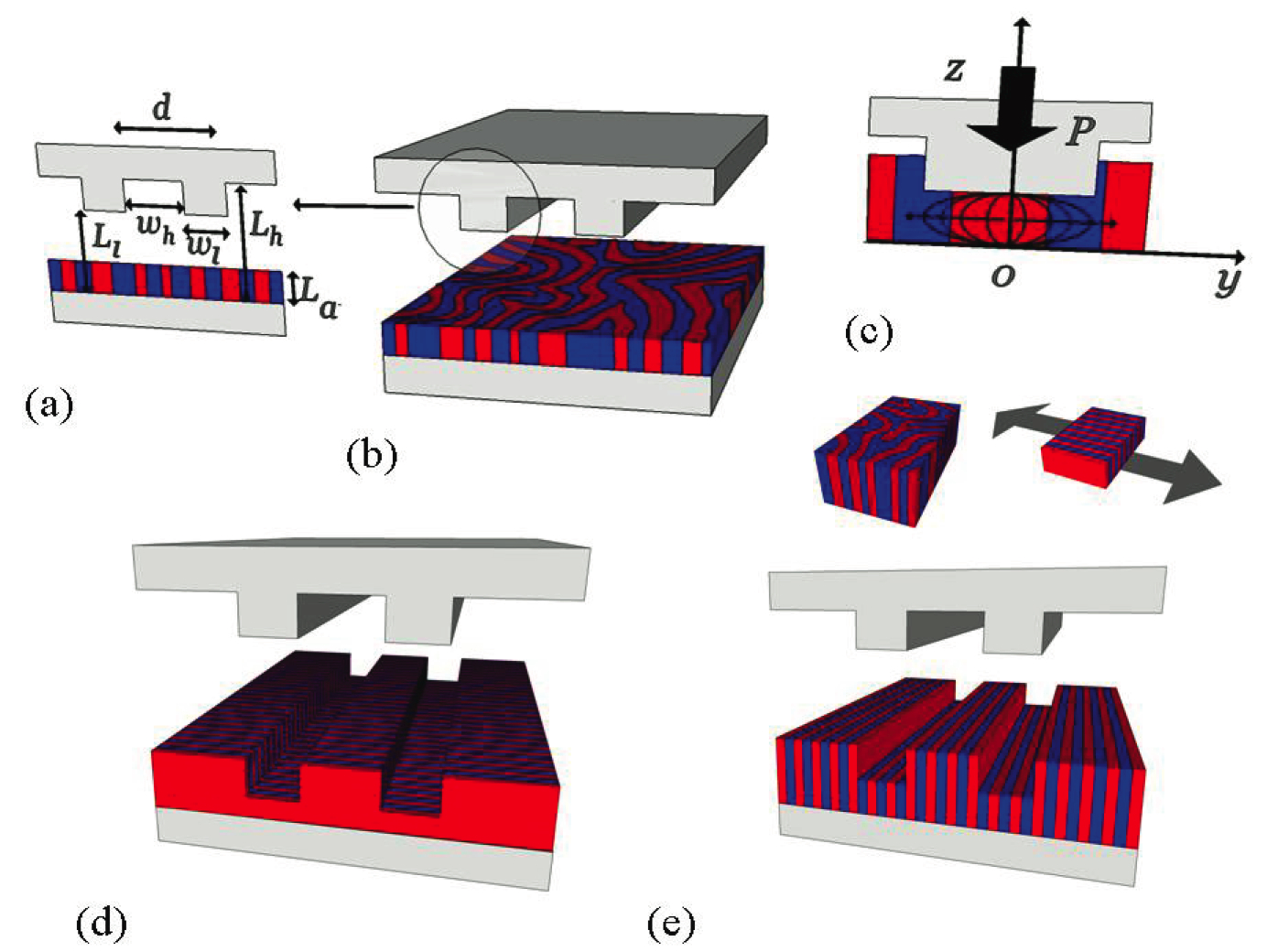

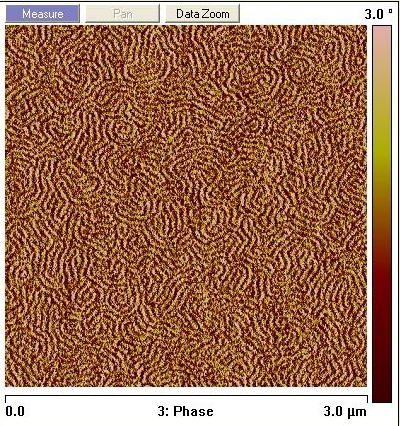

Copolymers on surfaces provide easily nanostructures thanks to their microphase separation.(see Fig.1) We can also guide these nanostructures perpendicular to the substrate and organize them in the plane by techniques of nanoimprinting (NIL, see principle Fig.2). In this thesis we now propose to control the growth of structure in the third dimension to produce structures with large aspect ratio which can be used as deep molds or for optical applications.

Fig.1: Lamellar phase oriented perpendicular to the substrate but disordered in the plane. The orientation perpendicular to the substrate

is described in MACROMOLECULES Volume: 42 Issue: 24 Pages: 9609-9612 Published: DEC 22 2009.

by surface field effect.

3) Copolymers self-assembled in the third dimension, application to metamaterials

The phase separation of copolymers can generate nanometer-sized structures that can be directed from a surface. We can thus access to these structures and consider them as molds of high spatial resolution for future applications in nanoelectronics. The possibility of obtaining periodic nanoscale structures also opens the way for the making of optical metamaterials.

We have recently shown (Macromolecules, 2009) that cylinders of diameter 40 nm or strips of same period could be erected on a surface with a suitable surface treatment. However the film thickness of copolymer that we can organize remains limited to about fifty nanometers. More generally, difficulties arise when one tries to control self-assembly of three-dimensional structures. A first problem is how to go from one point to another in space along a single continuous phase. However, such a topological control, would enable new electronic architectures and simplify the integration of self assembled systems into devices with aspect ratio larger than 1 (height> width of the pattern created). By etching these structures and a subsequent metallization one could also create metamaterials, periodic structures of sub optical wavelength to provide, among others, negative indices.

4) Mechanical properties of nanocapsules for ultrasound imaging

The ultrasound contrast agents (ACU) are nanocapsules which, when injected into the blood, can improve the contrast of ultrasound clinics. They can also be used as drug carriers by delivering the active ingredient in diseased tissue, thereby enhancing efficacy while reducing its effect on healthy organs.

The ACU studied in the laboratory consists of a shell surrounding a liquid core. In order to optimize their use in imaging and therapeutic applications, we want to evaluate and understand the factors that contribute to the improvement of their properties. This improvement is through better modeling of the mechanical behavior of objects is essential to understand the behavior in the physiological flow. We can make this model only if significant mechanical parameters are known. For this purpose the mechanism of the nanocapsules will be studied by atomic force microscopy (AFM). Indeed an AFM lever is not only a sensor to produce an image at the atomic scale, but also a sensor to record nano forces – of order nanoNewton or less.

In this mode the AFM nanoindentation tip is lowered onto the nanocapsule at a fixed speed which causes the indentation of the sample. The deflection (bending) of the lever depends on the hardness of the sample: a harder sample causes a larger deflection. Its bending is proportional to the force that the AFM tip exerts on the sample. From the deflection curves the indentation is deduced as well as the relationship between force and indentation if the response of the lever on a rigid surface is known. For this we first compare the bending of the lever on an infinitely rigid substrate such as silicon. Modeling of the curve force - indentation will then test different mechanical models of the nanocapsules. The aim is to go back to their Young's modulus, taking into account the possible adhesion of the tip to the particles. We will pay a particular attention to plastic effects that may occur, as well as viscoelastic effects that occur if the results depend on the speed of approach.

We can extend the thesis work to nanoparticles that serve as drug carriers. These nanoparticles, except for the constraints associated with a chemical transport of sufficient quantities of the drug and a very gradual release of the latter, also undergo mechanical stress in blood flow and the crossing of cellular barriers. Their mechanical properties are also crucial to quantify their optimization. In this case, the geometry is generally more complex than a simple compound ACU shell surrounding a liquid core. Moreover surface modifications can be made to modulate the adhesion of the particles.