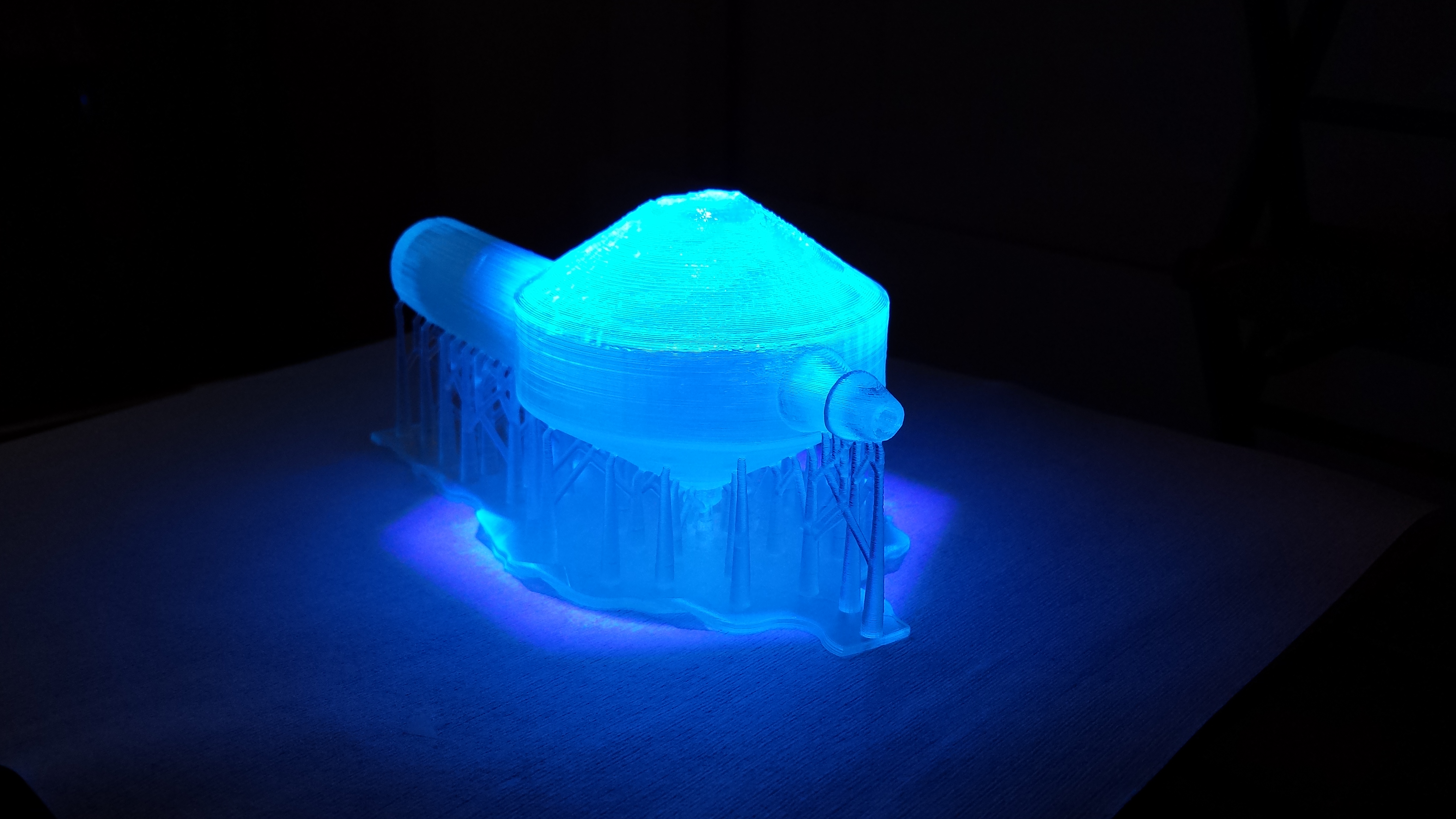

Additive manufacturing (AM) or 3D-printing is an increasingly widespread technique which is often described in a too limited manner as a source for rapid prototyping whereas it is a manufacturing process in itself. It is a new tool for instrumental research laboratories which can now easily manufacture by themselves a large variety of devices with optimized designs. We describes its application to a theme that has seen little developments in recent years that is ICP introduction system spray chambers. We undertake to print and study cyclone spray chambers by combining and comparing for the first time 3 different AM processes, 5 materials and 8 designs. The analytical performances of these spray chambers are compared with commercial glass and PFA chambers in terms of signal intensity, stability, oxide ratio, LOD and wash-out time. It shows that 3D-printed chambers manufactured produced by professional or low-cost printers for less than 1€ of material, provide better results in terms of sensitivity and LOD than costly commercial PFA ones. The limiting factor to achieve the performances in terms of sensitivity is the polymer wettability. LOD measured with polymer printed chambers are in the range or even outperform those measured with the glass chamber. This study also illustrates side arm nebulizer inner shape influence in the aerosol distribution and confirms the importance a free aerosol recirculation current around the nebulizer tip. Transfer tube efficiency is also questioned, it is found to be weakly detrimental to light elements sensitivity but shows no influence on heavy ones as well as nor on the stability or oxide ratio, whatever the element.

• › Interfaces, fluides complexes et microfluidique  Synthèse et caractérisation des nano-objets / Synthesis and characterization of nano-objects › Matériaux nanocomposites nanostructurés (cristallisés et matière molle) : de leur élaboration, à leurs propriétés. › Nano-chimie, nano-objets / Nano-chemistry, nano-objects

Synthèse et caractérisation des nano-objets / Synthesis and characterization of nano-objects › Matériaux nanocomposites nanostructurés (cristallisés et matière molle) : de leur élaboration, à leurs propriétés. › Nano-chimie, nano-objets / Nano-chemistry, nano-objects

• Laboratoire Interdisciplinaire sur l'Organisation Nanométrique et Supramoléculaire (LIONS)

• pas de titre • Inductively coupled mass spectrometry (ICP-MS) Analysis