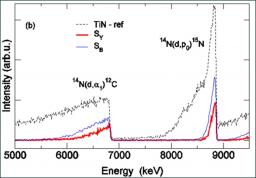

Figure 1: Focus on a selection of nuclear reactions induced by deuterons on nitrogen-14 measured after laser irradiation (1064 nm/ impulsion length 5 ns) under air. Red line: 8 x 1012 W/m2 (28 impacts) Blue line: 15 x 1012 W/m2 (68 impacts). Dotted line: TiN standard.

Titanium and its alloys are widely used in aeronautical, marine and chemical industries for their good mechanical properties, high resistance to corrosion, especially in sea water or human body, and low density, about 60% of steel density. However, tribological properties of titanium surface are poor with highly unstable friction coefficients and adhesive wear mechanisms which lead mechanical parts to seize up. Surface treatments are required to improve surface properties, according to the envisioned application.

Nitriding and carburizing are the most commonly used thermochemical treatments, but they must be done in highly oxygen-free atmospheres to avoid titanium oxidation. This rules out the possibility of local treatments. Laser induced modifications offer an alternative tool for modifying the surface composition by insertion of light elements (oxygen, nitrogen, carbon) present in the reactive atmosphere. Modified layers must have a high content of nitrogen to be hard enough to stand up to surface friction, while oxygen, localized in less crystallized phases, is also needed to accommodate friction without failure. Oxynitride formation appears then as ideal to reach optimal resistance.

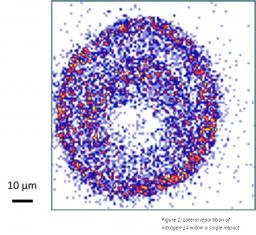

In order to understand nitrogen and oxygen insertion mechanisms, nuclear microprobe can be used to characterize laser treated layers. Use of deuteron induced nuclear reactions enables quantification of nitrogen and oxygen, as exemplified for nitrogen on figure 1. The intensity of the peaks is related to concentration whereas extension towards lower energies reveals insertion depth.

Microbeam scanning reveals also lateral distribution as seen on figure 2 which shows a nitrogen distribution within a single laser impact. Note that a standard laser treatment consists in covering a whole surface by overlapping single impacts.

Duration of laser impact has been found to be an active parameter. For short pulse duration, 5 ns, titanium oxynitride surface layers obtained under air contain up 40 at.% of nitrogen and 6 at.% of oxygen. For longer pulses, 35 ns, the insertion of nitrogen was negligible and the surface layers mainly composed of titanium oxides. This may be induced by the ablative effect of the laser which increases for short pulse durations and gives rise to the insertion of a higher amount of nitrogen in a shorter depth.

Tribological properties of the treated layers have been investigated by means of fretting experiments which consist in friction tests with a steel ball with short amplitude displacements (a few 10 µm, up to 20000 cycles).

Although the respective behavior of the layers differs for the first 1000 cycles, they all show a large improvement of the friction coefficient, in the 0.55-0.80 range, to be compared to 1.2 for bare titanium surface. The lower coefficients are achieved with high nitrogen contents.

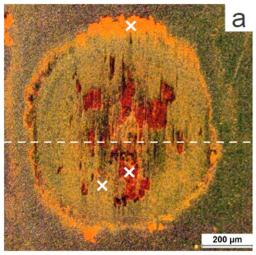

Above 12000 cycles, the friction coefficients are stabilized, due to the formation of fragments coming from layer abrasion, acting as a “third body” lubricating the interface. Optical micrographs, as presented figure 3, show the presence of particles outside the fretting trace, but also inside the contact zone. The red color suggests the presence of hematite (α-Fe2O3) coming from oxidized iron particles transferred from the steel ball, observation confirmed from Raman measurements.

Raman spectroscopy has also shown that peripheral fragments come from scaling (“egg shell” behavior), limited in magnitude when oxygen is present to help stress accommodation.

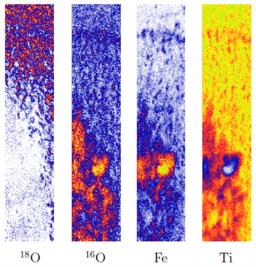

In order to identify the origin of oxygen in hematite particles, fretting tests have been performed on laser impacted surfaces under oxygen-18. Figure 4 shows clearly that titanium oxide surface had been eroded (oxygen-18) and that iron had been transferred from the steel ball to the sample surface and oxidized by ambient oxygen (oxygen-16).

The use of stable isotopes seems very promising for the understanding of the “third body” flowing, a crucial information to understand tribological properties.

References:

F. Torrent, L. Lavisse, P. Berger, J.-M. Jouvard, H. Andrzejewski, G. Pillon, S. Bourgeois,

M.C. Marco de Lucas "Wavelength influence on nitrogen insertion into titanium by nanosecond pulsed laser irradiation in air" Applied Surface Science 278 (2013) 245–249

L. Lavisse, P. Berger, M. Cirisan, J. M. Jouvard, S. Bourgeois and M. C. Marco de Lucas

"Influence of laser–target interaction regime on composition and properties of surface layers grown by laser treatment of Ti plates" J. Phys. D: Appl. Phys. 42 (2009) 245303

• › Caractérisation de matériaux pour l'énergie / Characterization of materials for energy  Materials for new energy technologies › Etudes métallurgiques par diffusion de neutrons / Metallurgical studies by neutron scattering

Materials for new energy technologies › Etudes métallurgiques par diffusion de neutrons / Metallurgical studies by neutron scattering

•  Institut Rayonnement Matière de Saclay • IRAMIS: Saclay Institute of Matter and Radiation • UMR 3299 - Service Interdisciplinaire sur les Systèmes Moléculaires et les Matériaux • Service Interdisciplinaire sur les Systèmes Moléculaires et les Matériaux

Institut Rayonnement Matière de Saclay • IRAMIS: Saclay Institute of Matter and Radiation • UMR 3299 - Service Interdisciplinaire sur les Systèmes Moléculaires et les Matériaux • Service Interdisciplinaire sur les Systèmes Moléculaires et les Matériaux

• Laboratoire d'Etude des Eléments Légers (LEEL) • Laboratory for light element studies